Afcons connects India’s longest railway tunnel

From constructing the world’s highest railway bridge to achieving breakthrough of the longest tunnel in Indian Railways’ history - Udhampur Srinagar Baramulla Rail Link (USBRL) project has consistently brought positive focus on Jammu & Kashmir. Afcons, a key player in this mission, has both these records to its credit. Chenab was in the spotlight last year for crowning the steel arch. This year, it’s the turn of Tunnel T49.

A remarkable journey culminated into the breakthrough moment, making this 12.75 km railway tunnel on Katra-Banihal section the longest in the history of Indian Railways. Interestingly, it has surpassed its USBRL counterpart, the 11.2-km Peer Panjal Tunnel along the Banihal-Qazigund section.

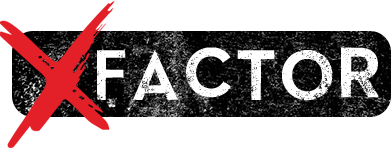

Afcons excavated 7.32km of the tunnel that connects Sumber and Arpinchala stations amidst several geological and weather-related challenges. Recalling the breakthrough moment, Project Manager Chandra Shekhar Dixit says, “This is an incredible achievement for the Indian Railways, for the nation, and for Afcons. The project team has worked extremely hard for this day.” Apart from T49, Afcons is constructing 4 other tunnels and 17 bridges (including Chenab Railway Bridge) for USBRL project.

The south portal of T49 lies in the picturesque Sumber village at an altitude of 1,400m, while its north portal is located near Arpinchala village at an altitude of 1,600m. Afcons made it to the breakthrough point from the north portal by excavating 4.07km from a single adit. “This is the most critical and longest length executed by any agency from a single adit. No other agency in entire USBRL project has excavated such a long distance from a single phase. We worked extremely hard to get here,” Dixit adds.

Apart from the challenges of working during biting cold winters (temperatures dipping to as low as -10 degree C), the team had to overcome the challenge of water ingress of 40-50 litres per second. “Since we were working on a downward gradient, we had to dewater almost 2 lakh KWH unit on average, per month. The water ingress was due to numerous aquifers and nullahs crossing the alignment,” the project manager recalls.

While more than 60 per cent of the tunnel length was executed in very poor rock class, extremely high deformation was observed in a 1.5km stretch. The team adapted various construction techniques such as enlargement of tunnel profile and introduced steel fibre reinforced concrete to speed up tunnelling.

Afcons began this eventful journey in 2015, battling a new challenge every day. Along the way, the original scope was revised to accommodate an additional 3.6 km escape tunnel bringing about a change in alignment. “We faced heavy snowfall, incessant rains that impeded vehicle movement every year and several local issues. Yet the project was completed within schedule. We are very happy to be contributing to our nation’s future,” Dixit says proudly.