An Arch etype of Extreme Engineering

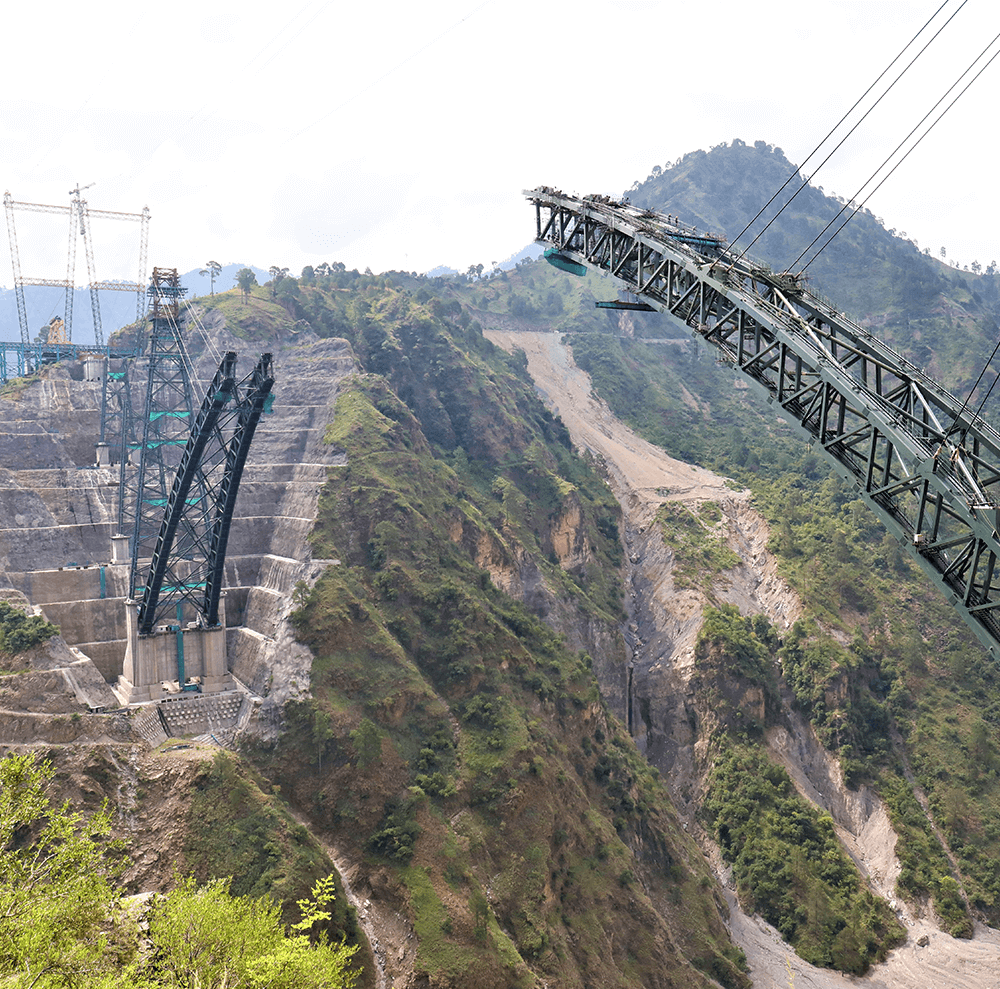

Constructing any bridge is a risky business. Imagine constructing a bridge that is hoisted 359m above a treacherous riverbed, and, exposed to gale-force winds between rugged mountain valleys. The construction of the Chenab Railway Bridge, which will be the highest single-arch railway bridge in the world, and, 35m taller than the Eiffel Tower, is a unique example in modern engineering. Amongst various things like viability, aesthetics, innovation, technology, and, geography that inspire awe and fear about this mind-boggling project, the threat to human life is the most real one. Few would dare to imagine working at such impossible heights beating extreme winters, torrential rains, and, excruciating summers. But Afcons’ engineers have overcome the odds and are within striking distance of their goal of making both arches meet over the Chenab river valley in Jammu and Kashmir.

While everything about the Chenab Railway Bridge project is extreme and unique in nature, arch erection is critical due to its intricate design and geometry. The erection of the mammoth segments (weighing 34 MT) is done with the help of the world’s tallest cable crane.

Here are some challenges involved in arch erection that make the activity extremely dangerous, complex, and tricky:

Dependency on Cable Crane

The cable crane is the backbone, and, the only source of erection activity in the project due to its location and height. Cable crane operations, however, get impacted due to heavy rains, gale-force winds, thunderstorm, and, lightening which affect arch erection productivity. So, proper planning, and, time-bound activity is of utmost importance.

Alignment of Erected Segments

Alignment of arch segments is very important for controlling geometry of the arch. This involves meticulous and regular survey during erection of arch segments. Temperature and wind monitoring are crucial during erection and survey. Surveys are done early in the morning to avoid temperature variation. Arch erection cannot be done if wind speed exceeds 15m/s. Temperature plays a crucial role during erection.

Unpredictable Weather

Due to unpredictable climate at a higher altitude, the arch erection activity is always fraught with danger. To mitigate the risk, adequate safety measures are adopted with additional activity time accounted for each arch erection. The hostile climate is a clear and present danger for engineers.

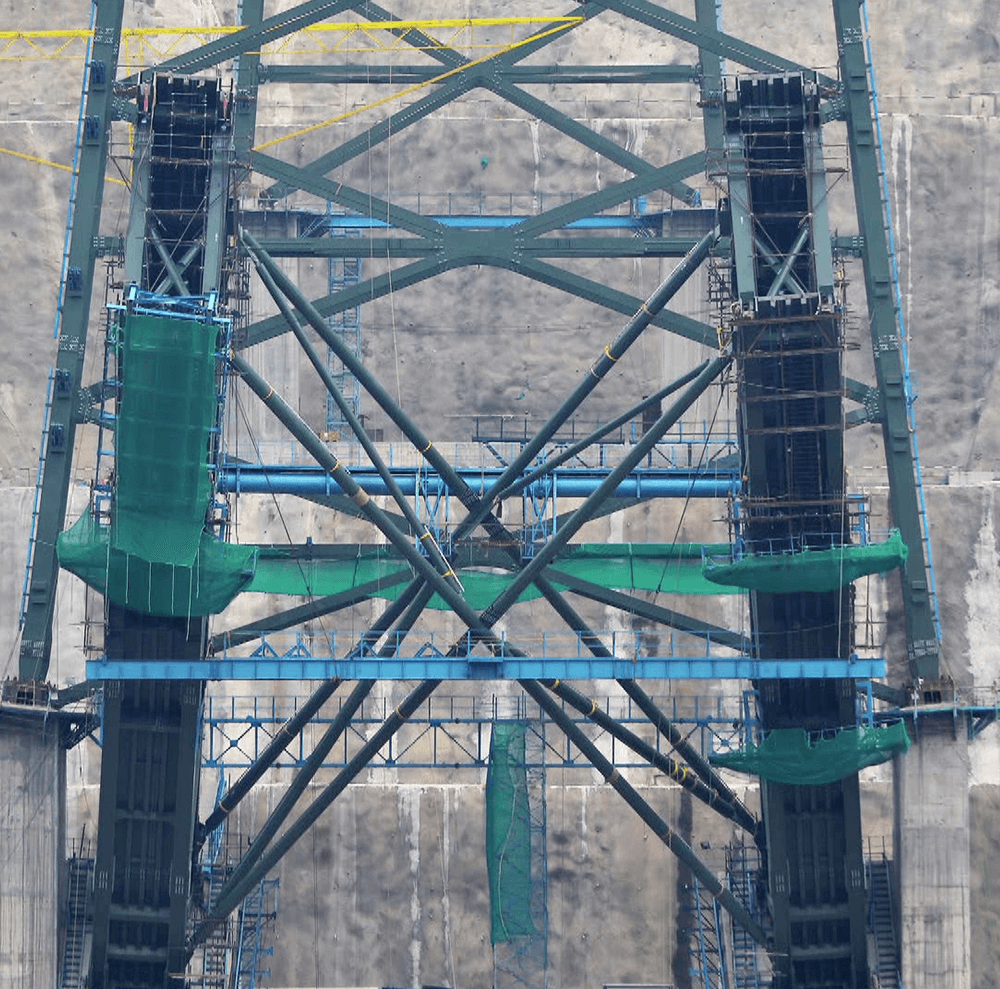

Erection of Temporary Structures

Besides arch erection, time-taking activities like frequent shifting of platform for each erected segment, and, providing scaffolding arrangement for bolting and torquing are repetitive events for every arch erected.

Long Wind Bracings of 40m length

Transportation: Transportation and shifting of wind bracing to erection location is a challenging task due to its length and weight. The uneven mountainous terrain makes transportation of the wind bracings extremely difficult.

Erection: Before erection of wind bracing, platforms must be provided at the location for ease of erection with proper safety measures. Pre-assembly must be done with required degree of inclination to erect as per the required geometry. Accordingly, arrangements must be made for lifting of wind bracings. After erection, in-situ welding is done at required locations which is a difficult activity under windy conditions.

Trial Assembly of Arch Segments

Before arch erection, the geometry (stress less) at ground level is checked so that any modification, or, alteration can be done on ground before erection. It’s extremely difficult and risky to rectify errors at such precarious heights after erection.

Erection of Split Segments (eccentric loading) in Multiple Lifts

Erection of such segments is one of the most difficult tasks due to involvement of multiple arrangements which includes platform erection and lifting arrangements. Due to eccentricity in loading of split segment, special lifting arrangements must be made.

Torquing of HSFG Bolts

Torquing plays a vital role in erection of arch. Shifting of equipment for torquing at such height and location is challenging and consumes time. Working at such elevations is very risky and needs specialised teams and platforms with safety measures in place. It is impossible to retrieve any HSFG bolt if it unfortunately slips and falls into the river from such height.

Stay Cable to hold Cantilever Arch

The stay cable is a vital part of arch erection. Stay cables are used for controlling the arch erection activity by using temporary steel piers (erected on permanent piers) and foundation on both sides of the valley. This is done for the first time in Afcons.

Here is a video of how the Wind Bracings are erected during the construction of the bridge.